Walnut blasting

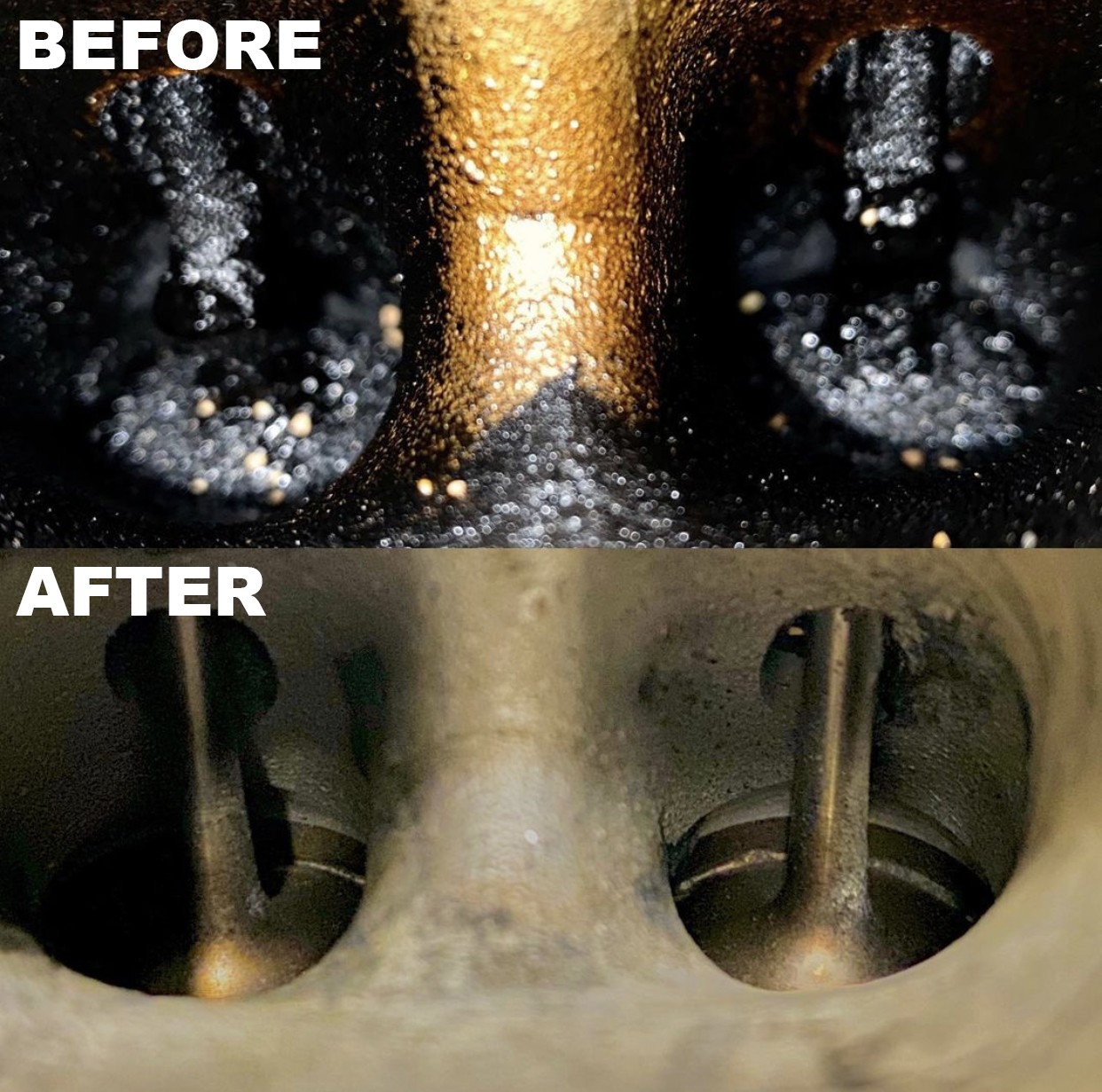

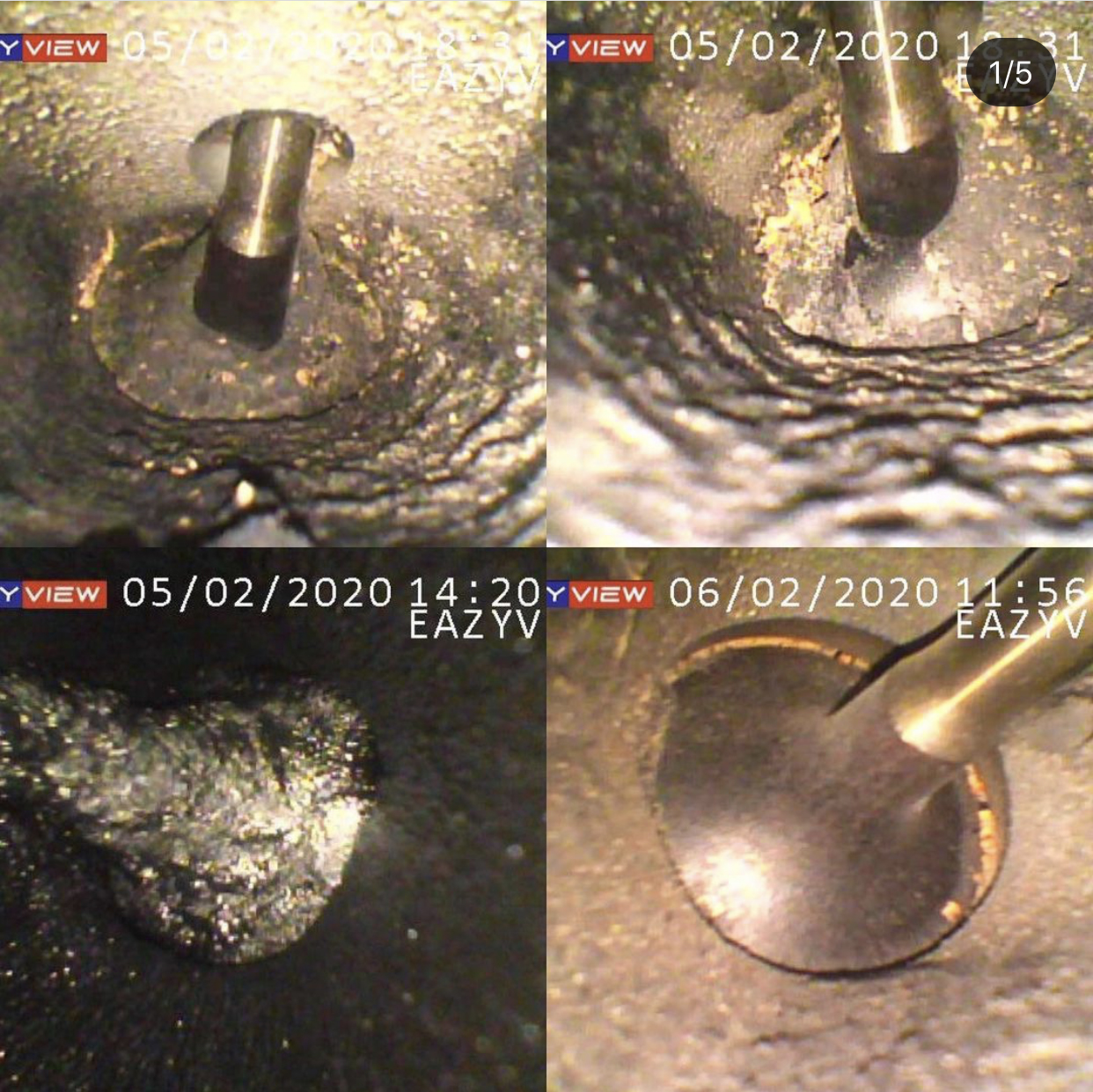

Walnut blasting is the process in which walnut shell granules are used in a high pressure system to clean the intake ports and valves. Intake valves and ports can suffer from a high level of build-up on both petrol and diesel vehicles, and is made worse by long periods of low speed driving (Especially in the London area).

Tighter emissions laws now mean that exhaust gas recirculation systems are fitted on more and more BMWs and MINIs. The effect of this is that more exhaust gases are circulated back into the intake system, and over time, carbon deposits build up on both the intake valves and ports. Direct fuel injection vehicles also suffer from the build-up because of blow-by gases from the crankcase system.

Why have a walnut blast carried out on my engine?

The carbon build up on intake ports and valves can have detrimental effects on the engine and can cause many issues ranging from engine management lights to reduce power and increased fuel consumption.

Other effects of this carbon build up could be a lumpy idle, poor throttle response, and vibrations from the engine.

Here at Turner Automotive you can have this clean carried out and not have to worry about your engine being disassembled and facing costly main dealer bills. The walnut blast is nice and simple, all that is required is removal of the inlet manifold.

Walnut granules have no detrimental effects on the engine, and ensures that the valves are cleaned in a less labour intensive way than removal of the cylinder head.